When it comes to concrete flooring, two common finishing options are often compared: Grind and Seal and Polished Concrete. Although they can appear similar at first glance – offering either a matte or glossy surface – the methods used and long-term results are quite different. In this article, we’ll explain the key differences, benefits, and considerations of each so you can choose the right flooring system for your specific application.

What Is Grind and Seal?

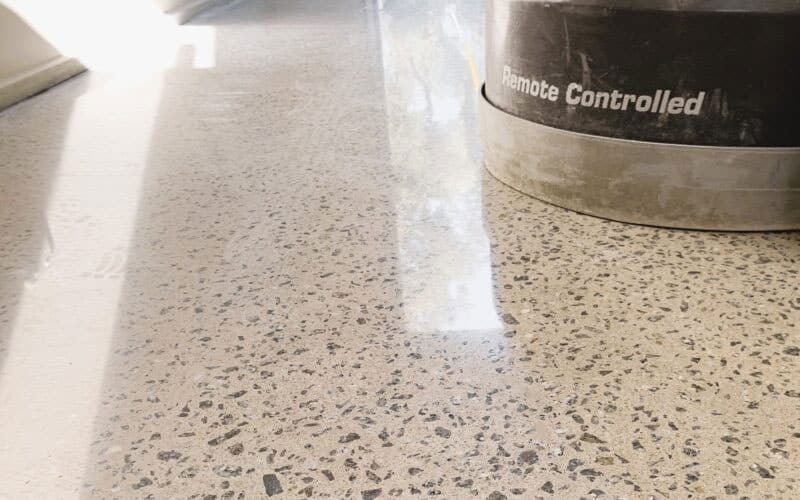

Grind and Seal involves mechanically grinding the concrete surface and then applying a topical sealer. The process is straightforward and cost-effective:

- Grinding: The surface is ground using a floor grinder equipped with diamond tooling. The correct bond type (soft, medium, or hard) is selected based on the concrete’s hardness.

- Surface Preparation: Cracks and holes are patched, and dust is thoroughly removed using vacuum and acetone mopping.

- Sealing: A topical sealer is applied in two coats, providing protection against UV rays, moisture, oil, and chemicals.

This method creates a consistent finish, as the final appearance depends more on the sealer than the concrete itself. It’s ideal for warehouses, garages, commercial spaces, and other high-traffic areas where ease of maintenance and affordability matter.

What Is Polished Concrete?

Polished Concrete is a more labor-intensive process that results in a sleek, refined finish:

- Multi-Step Grinding: The floor is gradually ground and polished with finer grit diamond abrasives.

- Shine Levels: You can choose from Level 1 (matte) to Level 4 (high-gloss mirror finish).

- Penetrating Sealer: Instead of sitting on the surface, this sealer chemically reacts with the concrete to form a water-repellent barrier from within.

Polished concrete is perfect for retail stores, showrooms, office buildings, and residential homes seeking a modern, upscale look with long-lasting durability.

Key Differences at a Glance

| Feature | Grind and Seal | Polished Concrete |

|---|---|---|

| Finish | Depends on topical sealer | Achieved through mechanical polishing |

| Durability | Good, requires periodic resealing | Excellent, long-lasting |

| Appearance | Uniform across most surfaces | Varies based on concrete condition |

| Maintenance | Easy, but resealing is needed | Low maintenance over time |

| Cost | More budget-friendly | Higher upfront investment |

| Best for | Industrial/commercial, outdoor floors | Showrooms, retail, residential floors |

Which One Should You Choose?

- ✅ Choose Grind and Seal if you need a cost-effective, durable floor with a consistent finish.

- ✅ Choose Polished Concrete if you want a luxurious look, high reflectivity, and a long-term solution.

Our Recommendations for Tools

Whether you’re grinding or polishing concrete, selecting the right diamond tools is crucial for performance and surface quality. We offer a full range of tooling compatible with walk-behind grinders and planetary machines:

- Diamond Grinding Plates (metal bond)

- Diamond Polishing Pads (resin bond, copper bond, ceramic bond, etc.)

- PCD Tools for Coating Removal

- Concrete Floor Bush Hammers

Need help choosing tools for your grinder brand? Contact us for expert guidance or check out our Diamond Grinding Shoes Catalog and Diamond Polishing Pads Catalog.

Final Thoughts

Grind and Seal and Polished Concrete are both excellent flooring systems – each with their own advantages. The best choice depends on your budget, design preference, and project requirements. If you’re still unsure, we’re happy to offer tailored advice based on your floor conditions and application.

Want a quote or technical advice?

Chat with us now via WhatsApp +86 13882641960 or send us photos of your current floor and equipment.