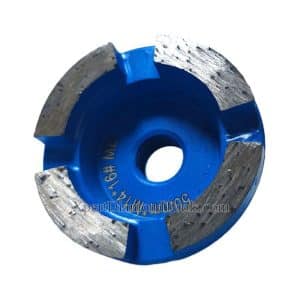

This 180mm diamond cup wheel features ten quarter round PCDs, for aggressively removing epoxy, glue, paint, mastic, varnish, and other stubborn floor coatings. Each PCD is welded reversed.

When PCDs (Polycrystalline Diamonds) are welded reversed, it means the sharp cutting edge faces outward, instead of the flat base being the exposed part. This design is common in PCD tools used for coating removal. The advantages include:

Advantages of Reversed-Welded PCDs:

-

Sharper Cutting Action

The sharp edge of the PCD directly contacts the surface, offering more aggressive and efficient coating removal. -

Better Material Penetration

The reverse orientation allows the PCD to “bite” into tough coatings (like epoxy, glue, paint) more easily, improving cutting depth and speed. -

Reduced Tool Load

Because cutting is more efficient, the grinder experiences less resistance and vibration, helping protect both the machine and the operator. -

Extended Life for Coating Removal

Reversed-welded PCDs wear more evenly and maintain their cutting ability longer, especially when used on soft or thick coatings. -

Cleaner Removal Surface

The sharp edge produces a smoother, more consistent removal of coatings, reducing the need for additional cleanup steps.